The 4ft Speed Square - A Builder's Good Companion

When you are working on a project, whether it's putting together a new shed or perhaps building some custom shelves, getting things straight and true makes all the difference. It's the kind of thing that separates a project that feels solid and well-made from one that, well, just looks a bit off. A tool that helps with this, a rather important one for anyone doing work with wood or other materials, is the 4ft speed square. It's a simple item, but it helps ensure your lines are where they should be, giving your work a finished look.

Thinking about projects that need things to line up just right, a tool that helps you mark out straight edges or angles is pretty handy. You want something that you can count on, something that gives you a clear line to follow. A 4ft speed square does just that, offering a straightforward way to get those measurements and marks down quickly and without much fuss. It's a piece of equipment that, in some respects, becomes a go-to for many different kinds of tasks where precision matters.

So, if you've ever wondered how folks get those neat, square corners or perfectly angled cuts, a lot of the time it comes down to having the right aid. This particular square, being four feet long, offers a good reach for bigger pieces of material, like those 4 x 8 plywood boards you often find. It helps you keep things aligned across a wider area, which is really quite useful for larger construction or building jobs, giving you confidence in your layout.

- Do That Thing With Your Tongue

- What Keyboard Does Mrlust Use

- Paul Rudd In This Is The End

- Katysancheskiii1 Videos Cristianos

- I Wish Italians Were Real

Table of Contents

- What is a 4ft Speed Square and What Does It Do?

- Why Consider a 4ft Speed Square for Your Work?

- How Does a 4ft Speed Square Help with Accuracy?

- What Are Some Common Ways to Use a 4ft Speed Square?

- Getting Started with Your 4ft Speed Square

- Caring for Your 4ft Speed Square

- Choosing the Right 4ft Speed Square

- The Lasting Value of a 4ft Speed Square

What is a 4ft Speed Square and What Does It Do?

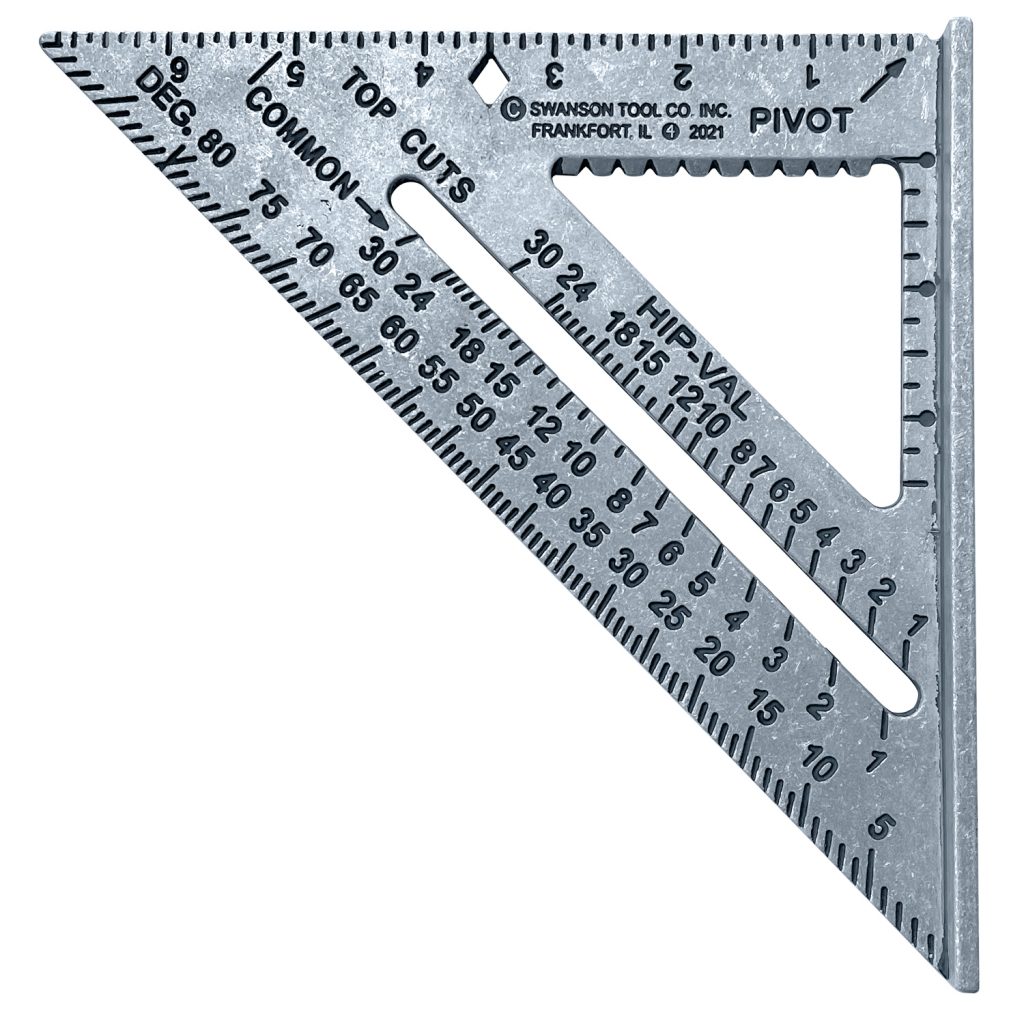

A 4ft speed square is, basically, a large triangular tool that helps you make straight lines and check angles. It's got a lip or a fence along one edge that you can press against the side of a piece of wood or other material. This allows you to draw a line that's perfectly at a right angle, which is 90 degrees, to the edge. You can also use it to mark other angles, like 45 degrees, which is pretty handy for miter cuts. It's a simple item, really, but its job is to give you a reliable guide for your cuts and layouts, ensuring your project pieces fit together just so.

The size of this particular square, at four feet, means it can reach across wider materials than smaller squares might. This is especially useful when you're dealing with those bigger sheets of plywood or long pieces of lumber. You can, for instance, draw a straight line all the way across a four-foot-wide board with one go, which saves time and helps keep your lines consistent. It's a tool that, in fact, makes the process of marking out larger components much less of a chore.

It's made from materials that are usually pretty tough, like aluminum or steel, so it can stand up to a lot of use on a job site or in a workshop. The markings on it are often etched in, which means they won't rub off easily, giving you a clear guide for a long time. This is important because you rely on those markings for accuracy, and you want them to be visible every time you reach for the tool. So, it's a piece of equipment built to last and help you get things right.

- Ebony Sock Worship

- Just Gimme My Money Original

- Lindas Toy Box Adult Videos Photos

- Heather Wyatt Finding Letters

- Livvy Dunne Cumtribute

Why Consider a 4ft Speed Square for Your Work?

You might wonder why someone would need a square this big, especially if they already have smaller ones. Well, the main reason is reach. When you're working with larger materials, like that 4 x 8 plywood often used for flooring or wall sheathing, a smaller square just won't cut it. You'd have to move it multiple times to draw a long line, and that increases the chance of your line being a little bit off. A 4ft speed square lets you make one continuous mark, which is a big help for keeping things straight and true. It truly makes a difference on bigger jobs.

Another thing is the speed part of its name. While it's a big tool, it's designed for quick and easy marking. You just hook the lip over the edge of your material, and you instantly have a reference point for a right angle. This means less fiddling around with measuring tapes and trying to line things up by eye. It's a straightforward way to get accurate marks down fast, which is pretty useful when you're trying to get a lot done. So, it really helps you work with a good pace.

Having a reliable square of this size also gives you a lot more confidence in your work. You know that your cuts will be square, or your angles will be just right, because you've used a tool that helps ensure that. This can save you from having to redo work, which, as a matter of fact, can be a real time-waster and frustrating. It's about making sure your efforts pay off with good, solid results, and a 4ft speed square helps achieve that feeling of certainty.

How Does a 4ft Speed Square Help with Accuracy?

The way a 4ft speed square helps you be accurate is pretty simple, but it's very effective. The key is its fixed angles. When you press the fence of the square against the edge of your material, the other edge of the square automatically gives you a perfect 90-degree line. There's no need to measure out angles or try to guess. It's just there, ready for you to draw along. This direct approach reduces the possibility of human error, which is pretty important when you want things to fit together without gaps. You are, in a way, relying on the tool's design to guide your hand.

For other angles, like 45 degrees, the square has clear markings or cutouts. You just line up the pivot point on the square with your material's edge, then swing the square until the desired angle mark lines up with the edge. This provides a clear guide for your angled cuts, too. It's a quick visual check that helps you get the angle right every single time. So, it's a bit like having a built-in protractor that's always set up for common building angles, which is really convenient.

Moreover, because it's a single, solid piece, there's very little chance of it flexing or bending when you're using it. This stiffness means the line you draw will be straight and true across its entire length. Unlike trying to draw a long line freehand or with a flexible ruler, the 4ft speed square gives you a solid, unchanging guide. This physical stability is what truly contributes to the high level of accuracy you can get with it, meaning your project parts will line up much better.

What Are Some Common Ways to Use a 4ft Speed Square?

One of the most common ways people use a 4ft speed square is for marking out cutting lines on larger sheets of material. Imagine you need to cut a piece of plywood exactly square. You simply lay the square down, hook its fence over the edge of the plywood, and draw your line. This ensures your cut will be straight and at a right angle to the factory edge. It's a straightforward method that helps keep your project pieces from looking crooked. You can, for instance, get a good, clean cut every time.

Another typical use is for checking if something is square. If you've just built a frame for a wall or a cabinet, you can place the 4ft speed square into a corner to see if it's truly 90 degrees. If there's a gap between the square and your frame, you know it's not quite square, and you can make adjustments before things are permanently fixed. This checking ability is pretty valuable for ensuring the overall stability and appearance of your construction. It's, like, a quick quality control check.

It's also often used for marking out roof rafters or stair stringers. These are pieces that require very specific angles and lengths, and getting them wrong can cause big problems. The markings on a 4ft speed square help you quickly find and mark the correct angles for these more complex cuts. It simplifies what could otherwise be a very tricky layout process, making it much more approachable for someone working on these kinds of building elements. So, it helps with those bigger, more involved parts of a project.

Getting Started with Your 4ft Speed Square

When you first get a 4ft speed square, it might seem like a lot of tool, but using it is pretty intuitive. The main thing is to get comfortable with holding it firmly against your material. You want to press the "fence" or the thick edge of the square, against the side of the board you're working on. This creates a stable base for the square, allowing the other edges to give you your reference lines. It's about getting a good, solid grip so the tool doesn't shift while you're marking. You'll find it's quite easy to get the hang of it, really.

Once it's held firmly, you can use a pencil or a marking tool to draw along the straight edge. For a 90-degree line, you just draw along the long side that's sticking out from your material. For angles, you'll pivot the square around the corner of your material until the angle mark you need lines up with the edge. Then, you draw your line. It's a quick, two-step process that gets you accurate marks without a lot of fuss. This makes it, you know, very user-friendly for a variety of tasks.

It's also a good idea to practice a little bit on some scrap material first. This helps you get a feel for how to hold the square and how much pressure to apply when drawing your lines. You'll quickly see how easy it is to get consistent, straight marks. This little bit of practice can save you from making mistakes on your actual project pieces. So, it's a bit like trying out a new pen before you write something important, just to get a feel for it.

Caring for Your 4ft Speed Square

Even though a 4ft speed square is built to be tough, giving it a little care can help it last even longer and stay accurate. The main thing is to keep it clean. Sawdust and dirt can build up on the edges or in the markings, which could make it harder to read or affect how it sits against your material. A quick wipe down with a cloth after you're done working can go a long way. It's a simple step that helps keep the tool in good shape, actually.

Storing it properly is also a good idea. You want to avoid dropping it or letting it get banged around, as that could potentially bend or warp it, making it less accurate. Hanging it on a hook in your workshop or keeping it in a dedicated spot where it won't get squashed is a pretty good approach. This helps protect its straight edges and ensure it remains a reliable tool for many years. So, giving it a spot of its own is quite beneficial.

From time to time, you might also want to check its accuracy. You can do this by drawing a line, then flipping the square over and drawing another line right next to the first one. If the two lines are perfectly parallel, your square is still true. If they diverge, it might have gotten bent. This quick check can help you catch any issues early on, before they affect your projects. It's, like, a simple way to make sure your measurements stay correct.

Choosing the Right 4ft Speed Square

When you're looking to get a 4ft speed square, there are a few things you might want to think about. One is the material it's made from. Most are aluminum or steel. Aluminum ones are usually lighter, which can be nice if you're carrying it around a lot. Steel ones tend to be a bit heavier and often feel very solid. Both are good choices, so it really comes down to what feels best in your hand and what you prefer for your kind of work. You can, for instance, pick one that feels comfortable to hold.

Another thing to consider is the markings on the square. You want them to be clear and easy to read. Some squares have markings that are etched in, which are generally more durable than painted ones that might wear off over time. Also, look at the contrast between the markings and the tool's surface. Good contrast means you can quickly see your measurements without straining your eyes. This is, you know, pretty important for working efficiently and accurately.

Finally, think about the thickness of the square. A thicker square generally feels more substantial and less likely to flex. While a thinner one might be lighter, a bit more thickness can provide a more stable guide when you're drawing long lines. It's about finding a balance that works for your specific needs and how you typically use your tools. So, it's worth taking a moment to feel it out before you make a choice, just to be sure it's the right fit.

The Lasting Value of a 4ft Speed Square

A 4ft speed square, in a way, offers a lot of lasting value to anyone who builds or makes things. It's not a tool that goes out of style or becomes obsolete. The need for straight lines and accurate angles is always there in construction and woodworking. This means that once you have a good quality square, it's likely to be a tool you reach for again and again, for many different projects over the years. It's, you know, a pretty dependable workhorse.

Its simple design is part of its strength. There are no moving parts to break or complex electronics to malfunction. It's a straightforward, mechanical aid that does one job very well: providing a true reference for measurement and marking. This reliability means you can count on it every time you pick it up, which is a comforting thought when you're in the middle of a project and need things to go smoothly. So, it truly stands the test of time.

Ultimately, investing in a good 4ft speed square is like investing in the quality of your finished work. It helps ensure that your cuts are square, your joints are tight, and your structures are plumb. These small details add up to a project that not only looks good but also performs well and lasts longer. It's a tool that supports good craftsmanship, helping you achieve results you can be proud of, which is, at the end of the day, what it's all about.

Detail Author:

- Name : Ms. Ruthe Herzog PhD

- Username : elmore21

- Email : johan.quitzon@boyer.biz

- Birthdate : 1974-03-18

- Address : 852 Lew Pines Suite 082 Gladysshire, IL 22944-1919

- Phone : +1 (618) 439-8511

- Company : Beahan, Emmerich and Kerluke

- Job : Computer Specialist

- Bio : Quis ea a est. Eaque voluptatem dicta accusantium enim. Vel officia ex vitae consequatur non placeat voluptas.

Socials

tiktok:

- url : https://tiktok.com/@lou_tremblay

- username : lou_tremblay

- bio : Eveniet et ipsa earum. Autem ab minus eum vel voluptate debitis.

- followers : 5192

- following : 299

linkedin:

- url : https://linkedin.com/in/lou.tremblay

- username : lou.tremblay

- bio : Enim aperiam eum ea aliquid dolor.

- followers : 1426

- following : 1400

twitter:

- url : https://twitter.com/tremblay2009

- username : tremblay2009

- bio : Architecto inventore quasi et pariatur. Iusto vero est rerum commodi blanditiis. Cum ab qui ex in aspernatur. Enim est dolorem ut.

- followers : 4809

- following : 820